|

|

|

|||||||||||||||||||||

| | HOME | PRODUCT | ASA/PVC COLOR PROFILE | |||||||||||||||||||||

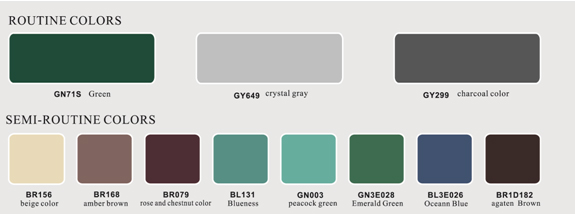

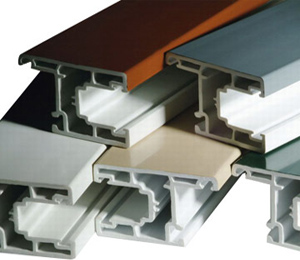

| Characteristics of High weatherproof Zhongcai ASA/PVC Corlorful Coextrusion Profiles: Our company is GE's only cooperation business in China. unique recipe and technology leads to super weatherproof and good anti-discoloration performance. Predominant shell structure of molecule endues the products with super ductility and makes them not easy to collapse. Advanced antistatic technology leads to the selfcleaning characteristics of products. Specific fillet weld treatment makes the product one integrated mass. Our products have passed the inspection for new scientific and technical payoffs,and were considered to have reached the advanced international standards. ASA/PVC Colorful Co- extrusion Profiles Why do we choose the ASA as our co-extrusion materials from various products in the market? I. Brief Introduction of ASA Developed in the 1970¡¯s, ASA is a ternary polymer which is composed by Acrylonitile, Styrene and Acrylate. It belongs to shock-resistance modified SAN resin. ASA is major products of GE Plastics which is subject to General Electric. In Aug. 2002, with GEOLY qua the registered trademark, GE Plastics introduce it to the market of Chinese PVC colorful co-extrusion profiles as a raw material for co-extrusion. II.Benefits of ASA Good Mechanical and Physical Property ¡¡ ASA was evolved from ABS, which is composed of Acrylonitile, Butadiene and Styrene. It preserves many excellent engineering plastics¡¯ mechanical and physical properties of ABS. ¡¡ Excellent Weather Resisting Property Because the double bond is easy to be opened by the ultra violet in the sunlight, the macromolecule materials with a double bond in tend to been decomposed. There is acrylic rubber without unsaturated double bonds in ASA, while in ABS the homologues material is bivinyl rubber with unsaturated double bonds. Consequently, the ASA products can not only resist degradation, ageing and color deterioration caused by the ultraviolet ray, but also reduce the decomposition or color changing caused by the high temperature during the oxidative manufacturing procedure in the atmosphere, and greatly promote the ant aging and weatherproof performance of materials. According to the test result, the ant aging performance of ASA is 10 times greater than ABS. Preferable Resistance to Elevated Temperatures The antistatic property of ASA products can reduce the deposition of dusts on the surface. III.Application fields of ASA Since the appearance of ASA, with its excellent weatherproof and typical mechanical properties similar to ABS, ASA has firmly established its fields of application. Field of automobile: After a longtime deflation, ASA will not changed into gray like special treated aging-resistant ABS (many micro fissures and cavitations erosion caused by the deflation and stream currents). Field of horticulture ASA was proved to be particularly applicable for the manufacture of shells of horticultural irrigation equipment and lawn cutter. Field of electricity ASA is preferential for the applications in making shells of much durable equipment such as sartorial, telephone, kitchenware and satellite aerial. Field of construction ASA/PVC mixture is used for roofing wallboard and window material. In this aspect, there has been ten years of applications in foreign countries. In U. S. A., with the fine surface quality and durative color, ASA is widely used in high level bathroom, sanitation ware and heat exchanger, which represents ASA, is a resistant material as for cleanser and disinfectant. Benefits of Zhongcai High Weatherproof ASA/PVC Colorful Co-extrusion Profiles I.Super weather resisting property GE employs American ASTM 26 Standard to test ageing performance of products. The test duration of them has exceeded 5000 hours. Their Delta E is much less than the maxim value specified in the standard. In order to have a sufficient investigation of their ageing performance, the test is in continuation. Compared the results of experiment which is done in Arizona with those Florida, the final Delta E was close to each other when irradiated the samples in different angles of arrival(5o,45o,90o). That is to say, when used in buildings and windows, the profiles will have a relatively consistent ageing process in different elevations such as in east, north, south, vertical plane and other slant. The two results showed that the profiles have a tiny chromatic aberration for different windows of the building. The ageing test of Zhongcai co-extrusion profiles given by National Research Center of Testing Techniques for Building Materials showed that they had reached the national standard for weatherproof performance. The step gray scale of them is 4 while the required one according to national standard is only above 3. II.Excellent Mechanical and Physical Performance The physical performance test of Zhongcai co-extrusion profiles given by national quality supervision, inspection and quarantine center on chemical building materials are as following:

III.Good Performance Resistant to Elevated Temperature IV. Good Surface Quality With homogeneous color and texture on the surface. Smooth and without obvious dents on the surface. The lightness of the surface is high, and the glossiness can exceed 70. V.The antistatic property of ASA products can reduce the deposition of dusts on the surface. VI.ASA has a similar mechanical working property to PVC, which can ensure the combined strength of co-extrusion profiles.

|

|||||||||||||||||||||